When most riders shop for a new bicycle, most of the emphasis is placed squarely upon the frame. Is it light enough? Is it stiff enough? Will it make me faster? Is it sexier than I am? The frame is really the heart of the bike. It is the truss that supports all other systems. So if the frame is the heart, then the soul would have to be found in the wheels. To reference Willian S. Burroughs in Words of Advice for Young People, "...not every soul is worth buying."

If riding a bicycle is, as Robin Williams believed, as close as you can get to human powered flight, the wheels serve to tether us to terra firma...if just barely. Wheels are an extension of our senses on the road--a palm to read the braille of the road or the scuff of the track. They transmit the earth below us into our bodies and we telegraph our reply back into them as the circuit of communication with our machines. Riding a route is to physically experience the terrain with all of our senses. The wheel is what gives a cyclist the super powers to climb up or to plunge down alpine slopes or skim the earth at blurring speeds powered by no more than our own legs. We owe so much of our saddle top experience to the input we receive from our wheels, and yet, they tend to be the most neglected of a bicycle's components as their value is the least understood by the consumer. Bike brands know this and the wheel becomes the sacrificial lamb in generating the most palatable MSRP.

For cyclists who understand the vital role an excellent set of wheels plays into ride performance (possibly more important that the groupset), a wheel upgrade is usually a first priority.

When it comes to building a complete, high performance wheelset, there are few manufacturers that can compare to the pedigree of DT Swiss, the wheel and shock manufacturer from Biel, Switzerland.

Although DT Swiss can follow its roots all the way back to the Swiss metallurgic culture of the 15th century (and possibly beyond), as the technology for drawing wire matured in and around Biel, the modern incarnation of DT Swiss AG was forged through a partnership amid the fractured remains of the United Wireworks in 1994.

Since its inception, DT Swiss has cultivated a loyal following with cyclists and with other brands in search of an OEM capable of supporting a reliable supply chain with the industrial experience from which to customize, launch and brand new wheelsets.

Although DT Swiss now offers a wide range of products for road and MTB cycling, the core of the company's success rides with its pairing of the now legendary 240 hubs with its patented spoke designs, including the super light weight Aerolite bladed spokes. The varied combinations of these two components have allowed DT Swiss to provide a complete, light, reliable and high performance wheelset in several configurations for a variety of uses.

DT Swiss products can be seen performing at the highest levels through the company's sponsorship of both road and MTB cycling teams. DT Swiss extends sponsorship to the professional peloton in IAM cycling as well as Team Stolting, 8Bar, Focus CX Team, Cube Action Team, Intense Factory Team, Scott Odlo, Yeti Factory Race Team and many others.

DT Swiss 240s Hubs

Here at TiC, I am usually very critical, wary and pretty standoffish when it comes to articles that appear to promote a product, brand or technology. Sometimes I am downright ornery. The equipment I use and write about is all based on my own (un?)educated selection, using my own money just like everyone else. As a consumer I always view product and brand promotion in the cycling press with a sprinkle of suspicion as there always seems to be a bit of patron politics at work and I am always left wondering what the reviewer really felt, but didn't want to offend their patron in print. I have always maintained full disclosure as part of my responsibility to the reader. This case is no different.

When I was offered the opportunity to visit the DT Swiss facility in Taichung, I had to give it some serious consideration. I finally decided I could, in good conscience, tour the facility and publish an article as long as I was free to write unobstructed and unhindered by those nice people at DT Swiss.

As a former customer of DT Swiss, it was my opinion that any weight my writing may lend to the company, will be matched in quality, reliability, support and corporate equity. If this had been another company I felt produced substandard products or lacked a wide net of support, I would not do it or I would not be shy about highlighting the negatives. I would hate it if my enthusiastic recommendation nudged someone over the edge to buying a product that turned out to be unsafe, with an evasive warranty, or complete shit. This matters to me.

DT Swiss-Taichung Office

In 2007, DT Swiss extended their operations to Taiwan, where they now employ 180 full-time office and production employees at three different Taiwan locations. The move put the Swiss manufacturer directly in the epicenter of the bicycle industry, which paved the way for closer cooperation between the supply chain, the manufacturer and the end user. It was a move that made it possible to inject DT Swiss production standards into a greater number of products and brands through OEM partnerships. You may be riding on DT Swiss technology without even knowing it.

Currently, DT Swiss handles production for Scott Syncros wheelsets, as well as supplying high-end hubs for other highly regarded brands, such as: Giant, Specialized, Trek and Cannonade-- allowing brands to market an in-house wheelset rather than having to reinvent... the...wheel (ahem!...sorry).

Moreover, DT Swiss handles OEM work from over 400 international customers, including: FFWD, Reynolds, ENVE, Intense, Pivot, Yeti, Canyon, Cube, Ghost, Rose, Orbea, Felt, Fuji, Ibis, Santa Cruz, Rocky Mountain, Norco, Devinci, KTM, Merida, GT and a whole universe of other established brands.

Bearings

Having worked in light industrial jobs a time or two in the past, the factory tour was completely familiar as we passed from floor to floor and room to room in a sequence that fits the logic of synchronized production. While manufacturing work is not necessarily Hollywood sexy, bathed in key lighting and dry ice, the facilities were clean, orderly, and a completely scaled replication of the home facilities in Biel. This allows the company to retain tight controls on quality and procedures.

Hub Production

Those storied front and rear hubs come into the Taichung facility from a regional supply chain that allows DT Swiss to better leverage its volume against the higher quality and cost of each component. This gives the company space to offer higher performance at lower price points; a factor many smaller companies do not have the clout by volume to attain and thus rely on lower quality internals to compete at a certain price point. Some may complain that DT hubs are not the cheapest, but there seems to be more of a companywide inclination toward the quality end of the spectrum.

The bearing seats, ring nuts and inner hub shells are lightly greased and then packed into place. The axle and bearing are then slid into place, followed by the second bearing. The ring nut and shims are then prepped and installed. Rear hubs have the ratchet greased followed by the spring to hold it firm and then the assembly is capped by the rotor. Adapters are pushed together from either end before the finished hub is sent out for labelling.

Aside from the individual parts, bearings, springs, caps et al, the hubs are completely assembled in-house, where the process and integrity can be tightly managed.

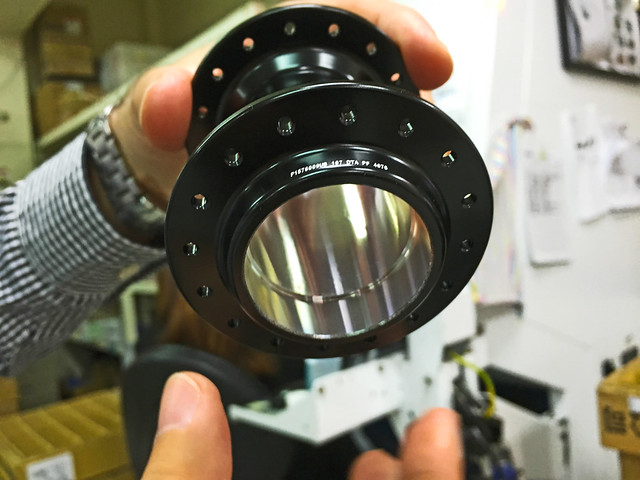

Hub Shells

In some cases, hub shells are laser etched with logos or design details per customer request. Giant specs a large number of laser etched hubs from DT Swiss.

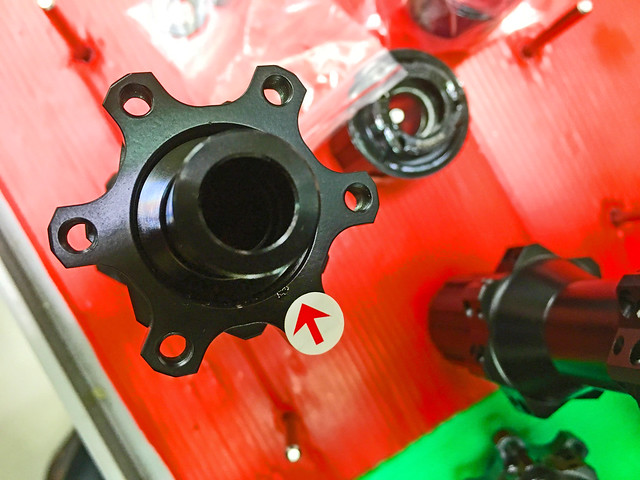

Quality Control

One thing I was trying to quietly keep an eye on, was the extent of the quality control systems in place at DT Swiss. When customers find their components were manufactured in Asia, there often seems to be an unfounded fear that the quality will somehow suffer. I think anywhere in the world there are cases where suppliers attempt to move the goalposts and get away with skipping procedures and of skimping on QC in an effort to shave a few more pennies off production. At DT Swiss, I saw similar controls as you would expect to find in any light industrial environment.

I once worked in a factory cutting Carl Zeiss lenses--arguably one of the most celebrated lenses for precision and quality. The quality controls and factory environment were, in a broader sense, nearly identical to DT Swiss.

Each hub is inspected along the way for flaws (these don't even have to be functional flaws) before it reaches the next stage in assembly. The hub pictured above has a slight inclusion in the coating and was duly marked and removed from production, and the cause traced and remedied.

Hubs are all marked with an individual serial number so that any anomaly can be traced, addressed and corrected.

Serial Numbers

Greasing

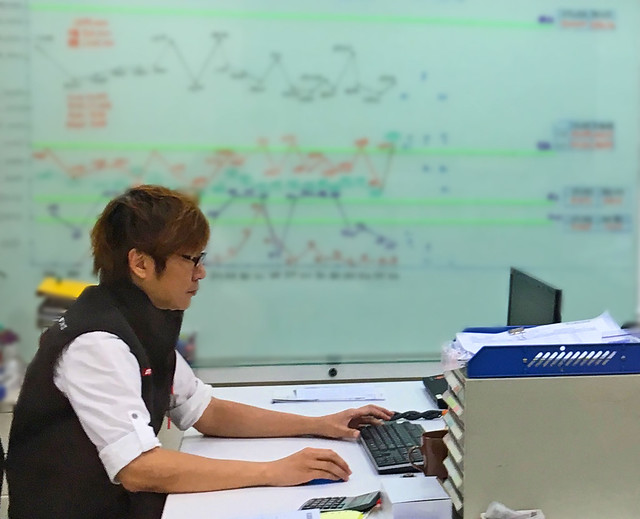

Production Management

I was also surprised to see how the production management monitored quality, output and customer orders. The atmosphere in the production office seemed collaborative and low pressure. This is very important in maintaining quality. Sometimes high pressure or the threat of instability in production can lead to an environment that reduces both quality and efficiency.

I know what an adversarial work environment looks like, and how little it accomplishes. This seemed like a healthy work environment filled with young professionals. I asked about employee compensation, and while I couldn't nail down specific numbers, I was assured that employees were both well trained and well compensated compared to similar occupations in the local economy.

DT Swiss Ratchets

My overall impression of DT Swiss hub production is that they run a very tight, professional facility with adequate quality control systems within an amicable environment that, from my brief tour, seemed conducive to maintaining a healthy exchange of vital information that could have some bearing on the final product. The employees worked with the speed of experience, but nothing slapdash and definitely not the lazy "差不多了" (whatever/good enough!) sentiments I have heard about from the work culture of some... neighboring countries... ahem!

The DT Swiss 240 series of hub is probably one of the best and most reliable hubs on the mass market and may even be comparable to some of the big names in smaller production houses. For years I have considered the 240 to be in the same elite category as Chris King, Phil Wood, Hope, and White Industries. I had actually been thinking about 240s the last time around if I hadn't bought a complete wheelset. True! DT Swiss uses their patented, "Star Ratchet" system in the freewheel to provide instant acceleration in an easily maintained package. One of my few complaints with using Chris King hubs was that they were finicky to the extreme. A couple hundred miles in the saddle and I would be adjusting the tension of the free hub. DT 240s have a reputation for being tight, light, durable and easy. They may not have the same bling factor as Kings, but for a rider who just wants to go fast and go now, the eye candy can come later.

For me, I really like easy. Living in Taiwan, space is a premium. You can't be spending every weekend with your bike, its components and internals, strewn all over the coffee table. You also can't be running back the have your hubs dissected after each surprise rain squall on an April afternoon. The less I need to remember about maintenance, the more I like it.

Ratchets

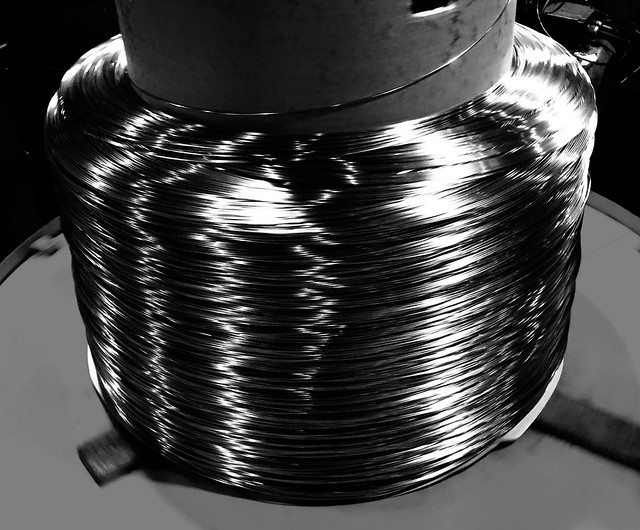

Spoke Coil

From the world of hubs, I was taken into the other world of DT Swiss, Taichung-- the world of spokes.

Spokes really give life to any wheel. Count, gauge, weight, stress, length, lacing, material and nipple quality all play a factor for giving any wheel its seemingly magical properties to transform the quality of any ride and provide the longevity that makes a wheel safe for thousands of kilometers of riding. At any given time the entire weight of a rider is balanced upon the tight matrix of tiny wires that keep our wheels from collapsing into a mess of tattered and bent material on the side of the road.

One of my Tuesday night rides involves cresting an unlit section of hill over the outstretched starry lights that clutter the void above western Taichung between Dadu and Shalu. The route takes me up and down 4 miles of gradients averaging over 7%, where I have hit 70kph on some sections of the descent, while keeping ahead of any vehicle traffic. Every drainage grate I hit, I feel a little bite of fear. It always scares the hell out of me that one of these nights a grate will reach up and grab my wheel or the impact will harm the wheel's integrity and in an instant. It is a sobering fear and a very human fear. Vigilance. Nobody wants to die on the road. It scares the hell out of me.

It also reminds me that I need to trust my equipment. If I feel I have made a good choice in my wheelset, I feel less fear and stay off the brakes (braking is a great way to slip). In cycling there is a psychological necessity to trust your equipment. If you are constantly in fear of some terminal failure, you will always hold back and never risk taking things too far. If a product has threatened to fail on you before, do you want to roll the dice a second time? I reach the crest of that hill, take a breath, look behind me, then jump on the pedals into the abyss. I know my bike will take care of me. The trust is there.

A well built, reliable, strong and true wheelset is essential for building that trust with your equipment and it really starts with the spokes. A spoke may be, individually, less than 2.0mm in diameter, but together in a wheel, they hold, not only the weight of the bike and rider, but they also must hold up to the stresses of velocity during heroic descents, track precisely under the forces digging into banked curves, and push against gravity wrestling up thigh snapping climbs.

Take your bike down and just spend a few minutes looking at the design of the wheel, and then appreciate how the evenly measures stresses pulling on that skinny hoop are what keep you from burying your face into the pavement on your next outing. The inside of a wheel is mostly air.

To make high quality spokes, DT Swiss spokes start their lives of drudgery as a massive 700kg wire coil. Each coil can produce approximately 100,000 spokes with DT Swiss turning out around 200 million spokes annually.

The wire is unspooled and slowly fed through the machinery that straightens the wire while avoiding any stress on the spoke that could compromise its structural integrity.

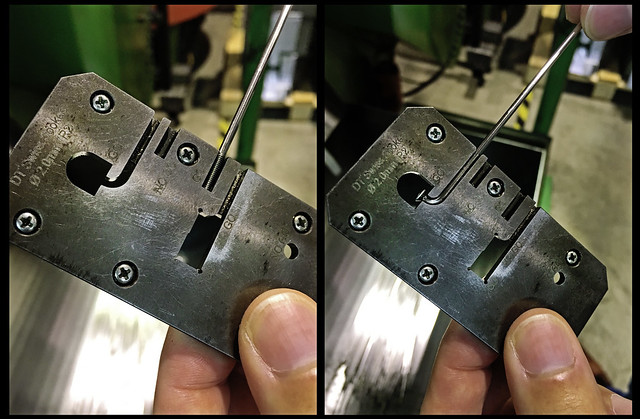

The spokes are cut to length, receive their threads, and J-bend before they are collected in the hopper.

Newly Minted Spokes

Spoke Integrity Check

The spokes are inspected for quality in their thread length and in the J-bend with the flange sitting flush. Spokes that do not meet DT Swiss standards are collected and rejected.

Rejects

Some DT Swiss butted and bladed spokes, spokes like the Aeorlite, undergo a cold forging process that subjects the spokes to a type of ultrasonic treatment for strength and lightness.

Another highly secretive process that remained hidden from view, behind imposing steel doors-- doors too technologically sensitive to be photographed-- was the process used to "blacken" spokes with a deep coloring process, which, unlike paint, prevents the spoke from discoloring from wear or from contact vibration in cross-spoke patterns.

Overstock

With custom orders, DT Swiss keeps a ready supply in overstock, so that customers can quickly respond to a rush order without having to wait for the machinery to be scheduled for another run. This adds flexibility and keeps production costs down. It is far cheaper to run a few extra units for overstock, than to set up for an entirely new production run.

DT Swiss keeps materials and supplies warehoused on site for immediate access. The entire facility seemed compliant with international regulations and guidelines. I recall having to jump through the ISO hoops several years ago to gain certification. Not long after the ISO evaluation succeeded, the procedures and guidelines were replaced with business as usual. I did not see anything at DT Swiss that remotely looked like business as usual.

I left feeling satisfied with the integrity and quality of DT Swiss products and production methods, and I felt my questions had all been answered in a satisfactory manner. It is only with this in mind that I felt I could, in good conscience, write an extensive, fair and thoughtful review of a wheelset offered by DT Swiss. Once the test period has concluded, Taiwan in Cycles will publish the review in full.

Now I have an excuse to ride the hell out of a set of wheels...like my life depends on it.

Stay tuned for a review of the DT Swiss Dicut RR21 Wheelset.

Many DT Swiss components may get their uncelebrated start within the walls of the nondescript Taichung production facility, but many of these nearly identical parts may lead the most extraordinary of mechanical lives, limited only by a rider's own sense of adventure.

Warehouse